A Glimpse Inside Our World

Watch our magic unfold in our expansive factory.

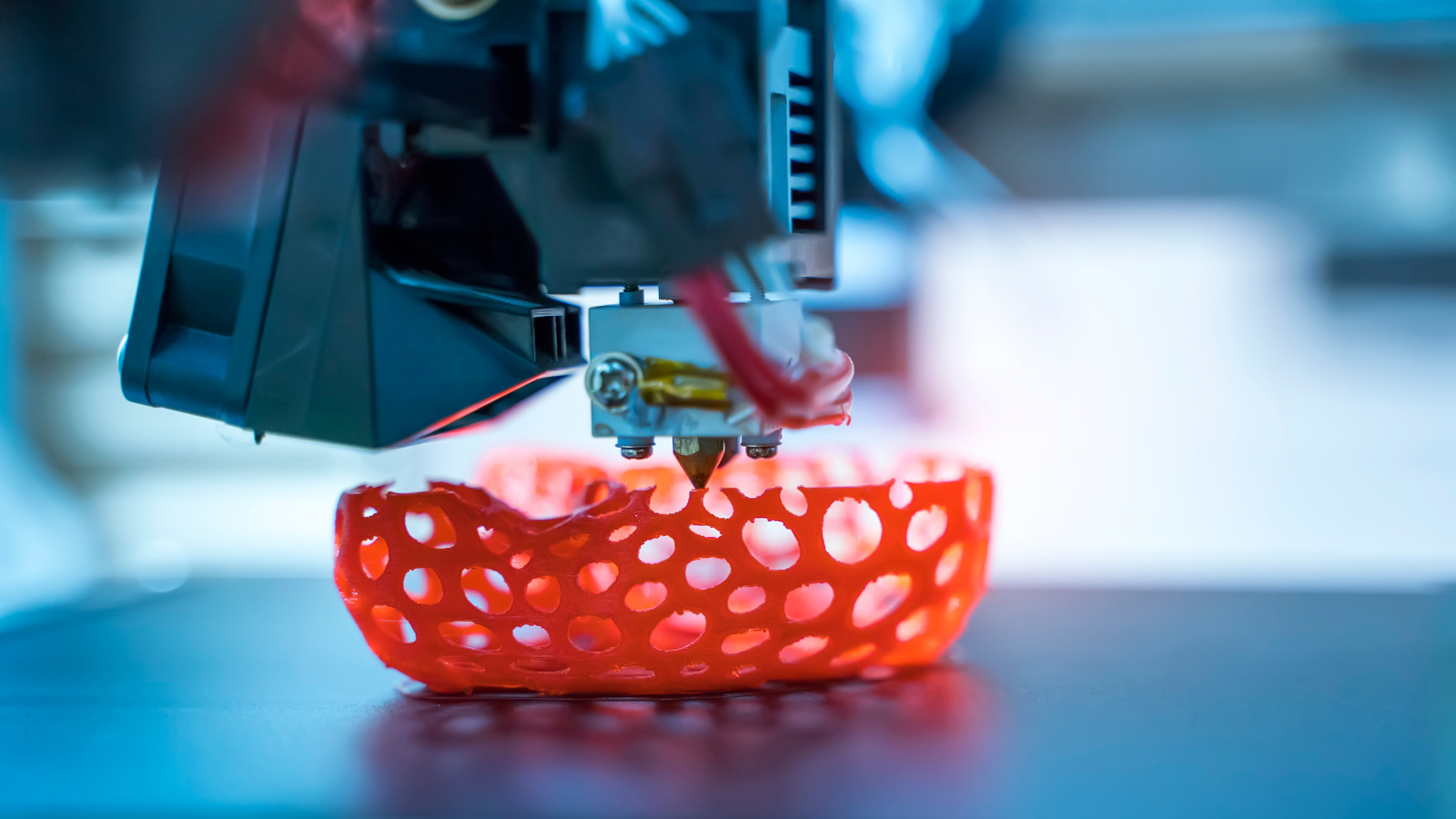

A vast space, home to 2000+ skilled artisans, where modern technology seamlessly blends with cherished traditional craftsmanship.

At our factory, every hand and every machine work in unison to create footwear that go beyond the ordinary.