Expansion

With a constant vision for expansion, we aim to produce 12,000 pairs per day by 2027. With an installed 1.1 MegaWatt Solar Plant, we save 57,200 Kilograms of CO2 every month, and it accounts for almost all of our daily energy needs.

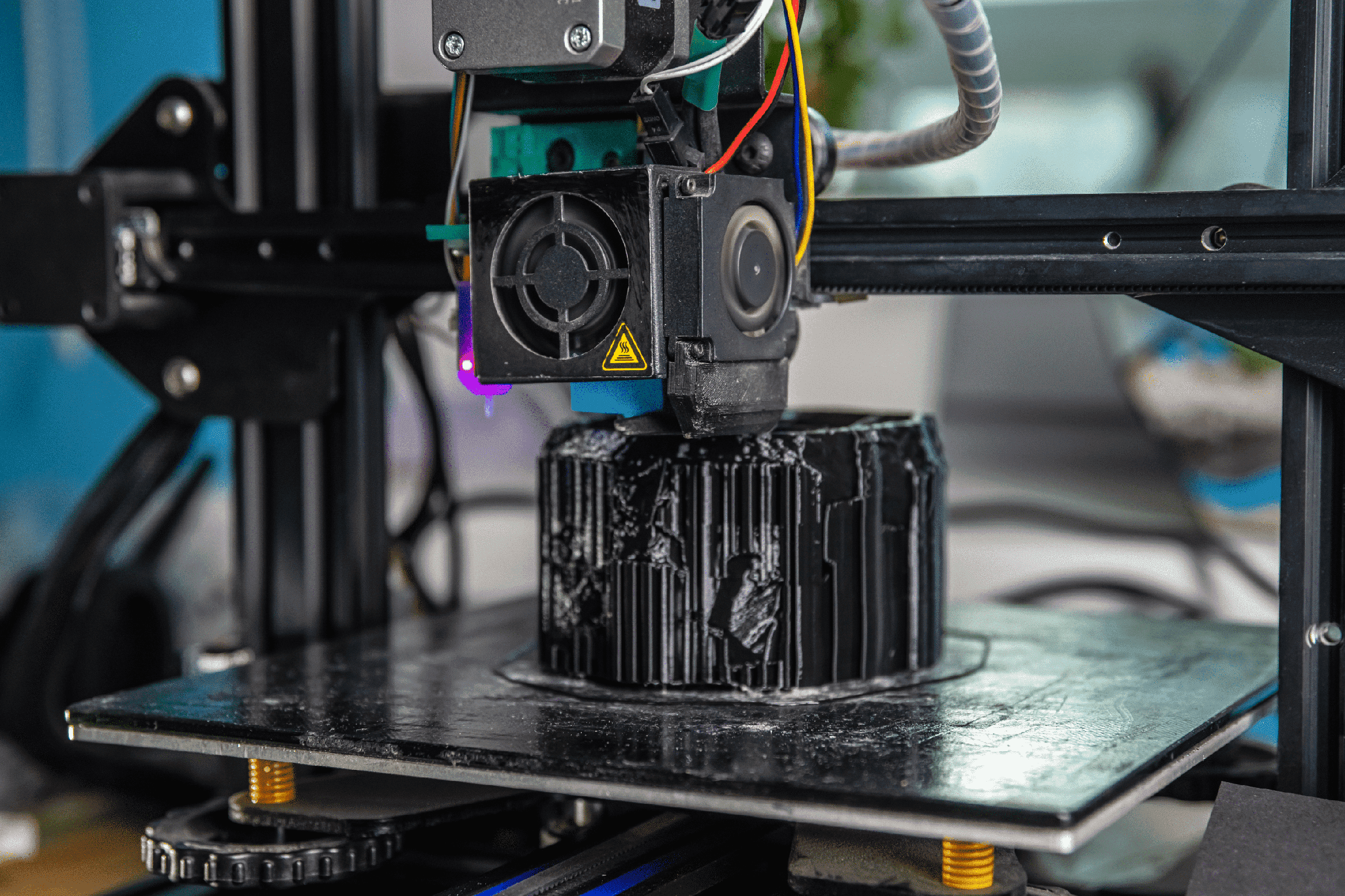

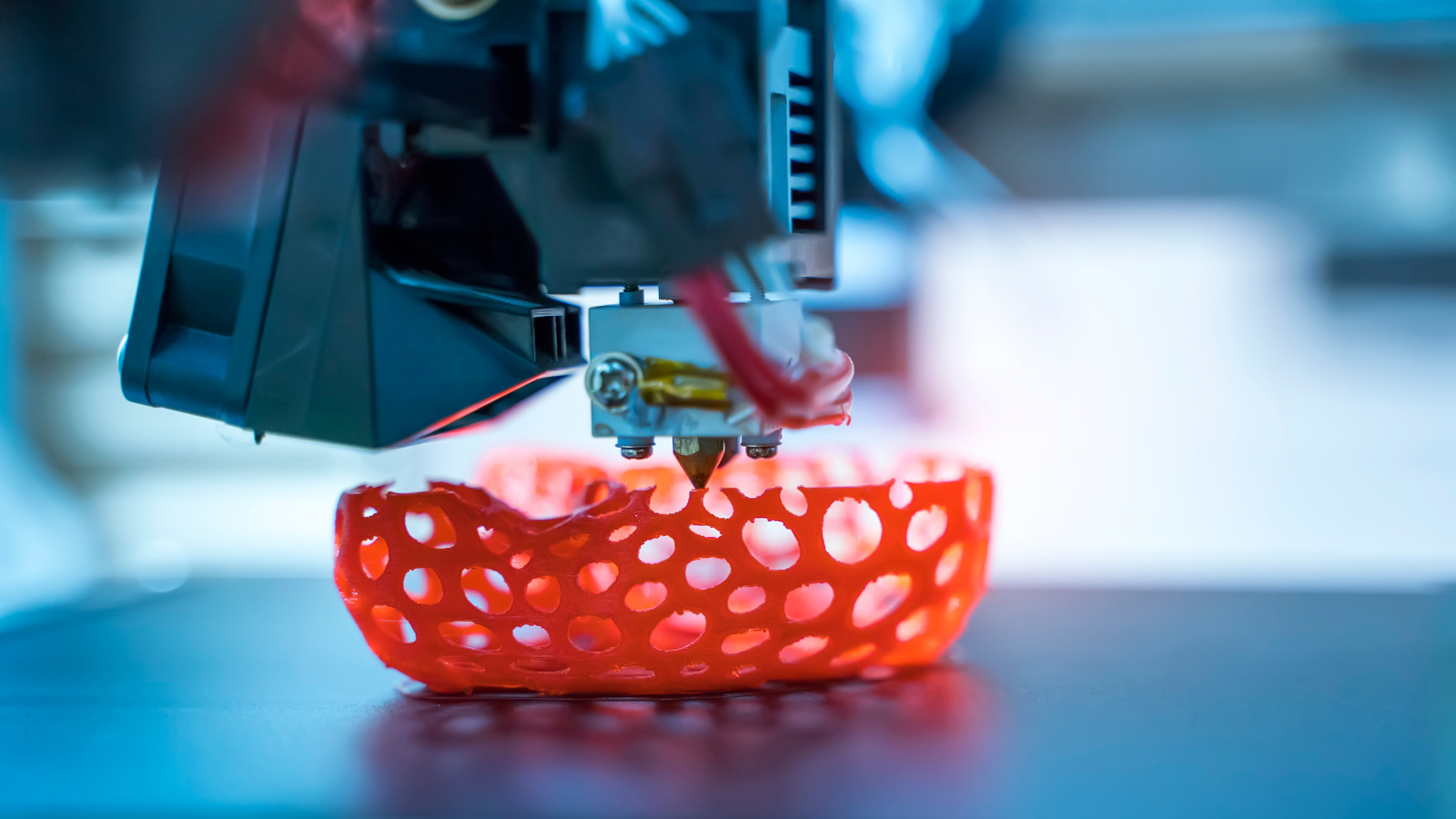

Dedicated Training Centre & 3D Printing

Investing in both our team's skills and our product innovation to secure our leading position in footwear excellence for the future.

State of the Art Production Unit

Our third production unit, equipped with four advanced lines, significantly enhances our manufacturing capacity to 2500 pairs daily. This expansion not only elevates our production capabilities but also ensures superior quality and craftsmanship in every pair, aligning with our commitment to excellence and market demand.

Advanced 3D Printing and Development

Our expansion includes a cutting-edge 3D printing facility, setting a

new standard for footwear innovation. This technology allows us to

rapidly prototype and refine new designs, bringing revolutionary

products to market faster and with unprecedented precision. It

represents a leap forward in our ability to customize and enhance the

footwear we offer to our partners

Dedicated Training Center

Adjacent to our production facilities, our expansive 100 ft by 70 ft training center is a cornerstone of our commitment to continuous improvement and workforce excellence. Here, employees master the latest footwear manufacturing techniques and safety standards, ensuring that our team not only grows in number but also in expertise.

We Believe in Ceaseless Innovation

Mass Production Excellence

Crafting over 12,000 shoes daily with precision and quality.

Cutting-Edge Materials

Innovating with advanced materials for superior comfort and durability.

Innovation_Hub

Solar-Powered Operations

Leveraging renewable energy to sustainably power our manufacturing processes.

3D Printing Prowess

Pioneering 3D printing techniques for customizable and efficient shoe production.